Products

Eco-friendly paper trays for multi-industry applications to meet different structural and packaging needs.

Facial Mask Bamboo Pulp Wet Pressing Craft Fine Paper Tray (Paper Plastic)

Perfumed White Wet-Pressed Sugar Cane Pulp Paper Tray (Papier-mâché)

Robot White Wet-Pressed Boutique Sugar Cane Pulp Paper Tray (Papier-mâché)

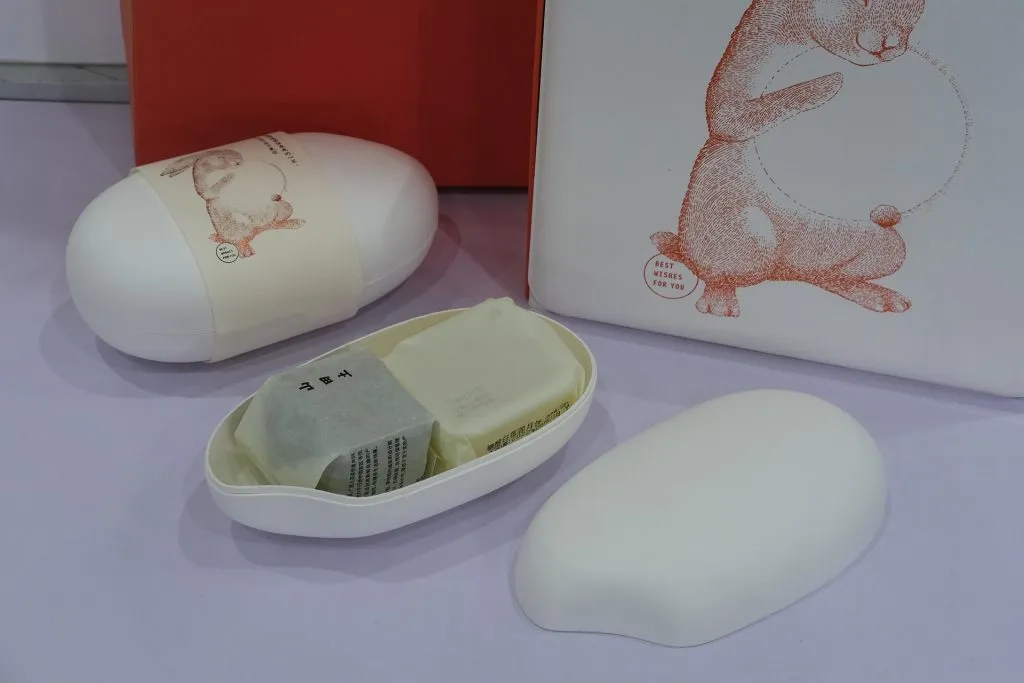

Boxes with paper trays (papier-mâché)

Ceramic cans yellow dry-pressed bamboo pulp paper tray (pulp molding)

Ceramic pot yellow dry press virgin wood pulp paper tray (papier-mâché)

Solutions

Provide paper tray application direction reference for multi-industry packaging application needs

Customization Process

Close coordination at every step of the process to ensure efficient delivery

Our Advantages

Source manufacturers, free design, free sampling

cooperative partner

Serving many brand-name customers and maintaining long-term cooperation

News

Gathering the latest information in the field of paper tray packaging

Main functions of pulp molded products

Pulp molding products is the rapid new packaging materials in recent years, is an excellent alternative to wood, is a three-dimensional paper technology. Pulp molding it to waste paper as raw material, in the molding machine by a special mold to shape a certain shape of the paper products, pulp molding, in addition to for lunch boxes, tableware, more to do with industrial cushioning packaging, fa...

Which is energy efficient, dry pressing or wet pressing for paper and plastic?

Paper-plastic is actually life everywhere in the packaging liner of various products, is a three-dimensional papermaking technology, it is a certain concentration of waste paper pulp, add the appropriate amount of chemical additives (such as moisture-proof agent, waterproofing agent, mildew agent, etc.), in the mold with a screen through the vacuum or pressurized method to make the fibers evenly distributed...

What are the advantages and disadvantages of wet press paper trays for packaging applications?

There are two kinds of paper trays, one is dry press paper tray and the other is wet press paper tray. Wet press tray is designed and manufactured according to the geometry, specification standards and protection requirements of the products to be packaged, the application areas include electronics, electrical appliances, communication equipment, computer accessories, glass, ceramics, lighting, handicrafts, cosmetics, wine,...